Automotive Component Research & Development (R&D)

Manufacturers of automotive components, much like original equipment manufacturers (OEMs), have found the accuracy, repeatability, and speed of response of Flow Technology’s turbine flow meter systems vital in obtaining the data required for component R&D work.

Among these automotive manufacturing applications are oil and air filters, polymer electrolyte membrane/proton-exchange membrane (PEM) fuel cells, fuel pumps, fuel injectors, transmission valve bodies, coolant and superchargers.

By offering a wide selection of flow meter sizes and bearing types/materials, as well as NIST-traceable calibration capabilities, experienced Flow Technology application engineers can provide the proper flow metering solution for the most demanding application.

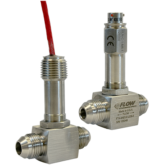

FT SERIES TURBINE FLOW METERS

Flow Technology’s FT Series turbine flow meters feature high accuracy and repeatability, compact size, and fast speed-of-response. The flow meters’ standard materials of construction are a corrosion-resistant and durable 316 stainless steel (SS) housing and 430F SS rotor. A selection of sizes and choice of construction materials can be specified for the housing, rotor, bearings, and shaft. Available end-fittings include NPT, AN (MS), Hose Barb, and SAE. An optional pressure tap is also available.

MICROLINK SMART PICKOFF

The microLinK Smart Pickoff is the world’s smallest and most compact temperature/viscosity/density compensated linearized CANbus turbine flow meter pickoff. Weighing only 65 grams, the microLinK Smart Pickoff has a wide operating temperature range, advanced averaging capabilities, a CANbus output providing access to all process variables and totalizers, and a 0/4-20mA linearized flow output. The microLinK is easily configurable, and all data is available using Visual Link programming software.

MICROLINK DISPLAY

The microLinK Display is a compact, lightweight, and easy-to-use rate/totalizer display to monitor CANbus data from the microLinK Smart Pickoff. The display can also be used to change the configuration of a microLinK Pickoff. Embedded LED lights provide real-time feedback of the communication status, and display brightness and contrast can be adjusted to suit the installation environment.